Calibration Services for Plastics and Rubber Manufacturing

Precision Calibration Services for Plastics and Rubber Manufacturing

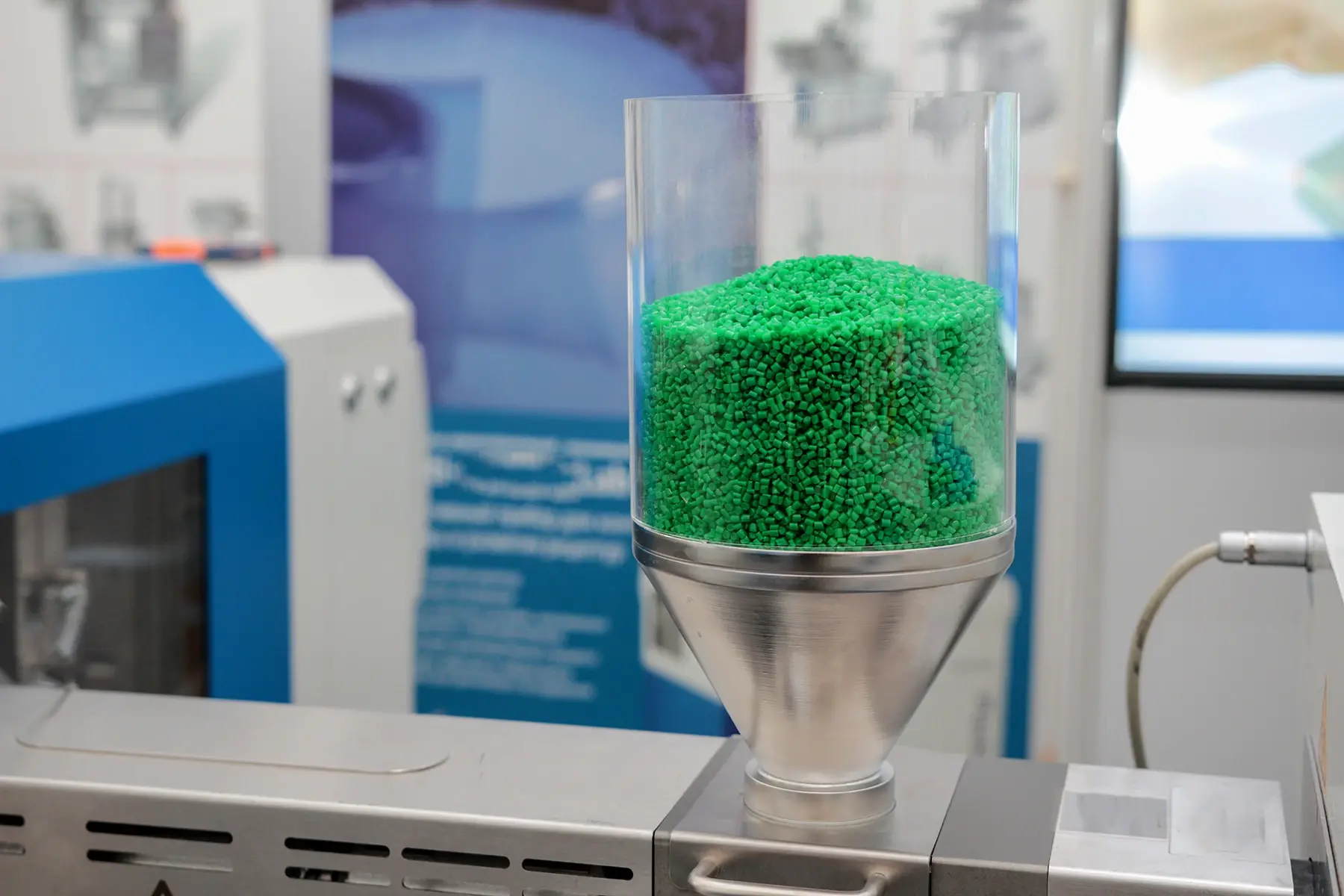

The plastics and rubber industries form essential pillars of modern manufacturing, creating materials and products that enable countless applications from automotive components and medical devices to packaging and consumer goods. From polymer processing and material testing to quality control and performance validation, plastics and rubber manufacturing requires precise measurement and reliable instrumentation that ensures material properties, product performance, and regulatory compliance.

CMG Sales, backed by the trusted Accredited Labs network, provides comprehensive calibration services designed for the unique requirements, diverse applications, and quality demands of plastics and rubber manufacturing operations.

The Foundation of Material Science and Manufacturing Excellence

Plastics and rubber manufacturing represents the transformation of raw polymers into engineered materials with specific properties, performance characteristics, and application requirements. Material properties such as strength, flexibility, temperature resistance, and chemical compatibility must be precisely controlled and validated to ensure product performance in demanding applications. When measurement systems fail in plastics and rubber operations, the consequences include material defects, product failures, customer complaints, and potential safety hazards in critical applications.

The plastics and rubber industries serve diverse markets with varying quality requirements, regulatory standards, and performance expectations that demand sophisticated measurement systems and comprehensive quality control programs. Modern polymer processing uses advanced technologies, automated controls, and real-time monitoring that depend on calibrated instruments for process optimization and consistent product quality.

Industry Standards and Regulatory Compliance

ASTM International Standards

Plastics and rubber testing follows comprehensive ASTM standards that specify testing procedures, sample preparation, and acceptance criteria. Our calibration services ensure compliance with ASTM standards and support testing laboratory accreditation and quality programs.

International Organization for Standardization (ISO) Standards

Global plastics and rubber markets require compliance with ISO standards for testing methods, quality management, and environmental requirements. Our services support ISO compliance and international market access for polymer products.

Medical Device Regulations

Medical grade plastics and rubber materials must comply with FDA regulations, biocompatibility requirements, and medical device standards. Our calibration services support medical application compliance and regulatory submission requirements.

Environmental Protection Agency (EPA) Regulations

Plastics manufacturing must comply with EPA environmental regulations for emissions, waste management, and chemical safety. Our calibration services support environmental compliance and monitoring requirements.

Why Choose CMG Sales for Plastics and Rubber Calibration

ISO/IEC 17025 Accreditation and Polymer Industry Expertise

We operate under the rigorous ISO/IEC 17025 standard while maintaining specialized expertise in polymer science, plastics processing, and rubber manufacturing. Our technicians understand polymer materials and provide calibration services that support material quality and manufacturing excellence.

Process Control and Manufacturing Support

Polymer processing requires accurate process control and monitoring systems for temperature, pressure, and material flow. Our process calibration services ensure optimal processing conditions and support manufacturing efficiency and product quality.

Multi-Industry Application Expertise

Plastics and rubber serve diverse industries with varying quality requirements and regulatory standards. Our team understands different application requirements and provides calibration services that address specific industry needs and compliance requirements.

Quality System Integration and Documentation

Plastics and rubber manufacturers implement comprehensive quality systems that require calibration integration with quality management and process control. Our services provide quality system support and documentation that enhances manufacturing quality and competitiveness.

Supply Chain and Multi-Site Coordination

Plastics and rubber companies often operate multiple facilities and complex supply chains that require coordinated calibration programs. We provide consistent service quality and documentation across multiple locations while supporting supply chain integration.

Powered by Accredited Labs

As part of the Accredited Labs family, CMG Sales, Inc. combines local, personalized service with the resources and expertise of a national calibration network. This partnership ensures consistent quality, technical support, and the capabilities needed to handle your most challenging calibration requirements.

Personalized Customer Service

We believe in building long-term relationships with our customers. That's why we prioritize clear communication, consistency, and reliability. Our team takes time to understand your specific needs, applications, and challenges, so we can provide calibration solutions that support your operational goals and quality objectives.

ISO/IEC 17025 Accreditation

We operate under the rigorous ISO/IEC 17025 standard, which demonstrates our technical competence and quality management system. This internationally recognized accreditation means our calibration results are accurate, reliable, and globally accepted. Our technicians undergo continuous training in evolving technologies and techniques.

Comprehensive Documentation

We go beyond calibration certificates, providing you with the documentation and support your quality system needs. Our detailed reports include measurement data, uncertainty analysis, and recommendations for calibration intervals. We also maintain comprehensive records for easy certificate retrieval and audit support.

Flexible Service Options

We understand that every business has unique operational requirements. That's why when possible we offer on-site calibration services to reduce your downtime. For instruments requiring controlled environments or specialized equipment, our fully equipped laboratories provide optimal calibration conditions.

Fast Turnaround Times

Production schedules don't wait for calibration delays. We prioritize quick turnaround times without compromising quality, helping you maintain operational efficiency while meeting calibration requirements. Our streamlined processes and scheduling ensure your instruments return to service as quickly as possible.

Audit-Ready Calibration in 3 Simple Steps

Submit Your Equipment List

Send us a list of the equipment you need calibrated, and we’ll provide a tailored quote with clear pricing—no hidden fees.

Schedule Your Calibration

Choose a convenient time for a mobile or on-site equipment calibration. Our certified technicians ensure precision and compliance with ISO/IEC 17025 standards.

Stay Compliant & Audit-Ready

Receive detailed calibration reports and certification, giving you peace of mind for audits and operational excellence.